On the path to more sustainable product design (part two)

Design Principles

“Design Principles” is the second part of a two-part series.

In this article, we illustrate a few design principles and, for each, examples of practical strategies that we can adopt - alongside better material choices - to strengthen our efforts on the path to more sustainable product design.

In case you have missed it, in part one of this series, we introduced how, as designers, we can contribute to the shift from a linear disruptive economy to a more circular model by keeping tabs on material choices early on in the design process. However, since the footprint of a product is not determined by its materials alone, for us, designing for sustainability continues beyond better material choices.

It is a commitment that revolutionises the whole design process, from ideation to production, and goes even further.

Product design is successful when it understands the end-user customer and solves real problems for real people with empathy and knowledge of their habits, behaviours, frustrations, needs, and wants. However, designing for sustainability asks us to introduce an additional dimension. Successful sustainable product design does all of the above. Still, it also designs out harm already during the design process before it even happens.

How can we achieve this in practice?

The R-ladder describes strategies for moving towards a more circular economy. As a rule of thumb: the higher on the ladder, the higher the level of circularity.

In practice, as idealistic as it might seem, a systemic rethinking of how we design is needed to achieve successful and sustainable product design. To accomplish so, we can introduce design principles that support positive outcomes for the whole (eco)system.

The design principles for designing for sustainability come from traditional design approaches. Others repurpose or derive from the many schools of thought practising and supporting sustainability - such as the Circular Economy and its R-ladder. However, they all have a common characteristic: they push us to zoom out and use systems thinking in the design process to consider and combine various focuses and strategies for an even more significant outcome.

Here’s a list of some of them:

Design for Reducing

Design for Recycling

Design for Rethinking

Design for End of Life

Design for Repair & Refurbish

Design for Reuse & Repurpose

Design for Less

Design for Emotion

Design for Durability & Longevity

Design for Disassembly & Modularity

Design for Sustainable Behaviours & Use

Design for recycling

FROLIC studio. Award-winning materials.

Sometimes materials are so bound together (e.g., with additives or in the moulding process) that they become too difficult to separate. At times, the value of some recycled materials is less than the cost of producing them. These are typical cases in which recycling is almost impossible. Humans opt for convenience: if recycling a product is not convenient or apparent, it is more likely to end up in a landfill. Therefore, a product must be easy to recycle to increase the likelihood that recycling will happen.

In the design phase, we can make a product easy to recycle, thus ensuring higher chances of material recycling and facilitating more efficient and successful recycling outcomes.

Note: Diverse waste disposal options exist, each with pros and or cons regarding sustainability. Waste prevention and reuse are the most preferred, followed by recycling (including composting) and energy recovery (through incineration). Disposal in landfills should be the very last resort. Design for recycling is not always the best choice if we can opt instead for design choices that will allow our product not to become waste from the get-go.

-

Considering materials compatibility with recyclable waste streams

Using fewer materials and parts

Not using additives on materials: e.g., no glues, paints or other coatings to avoid material contamination

Designing for disassembly and modularity: effortless separation (e.g., by preventing the use of adhesives) of components made from different materials

Researching what the recycling regulations for each material are in the country where the product gets distributed, as each country has its recycling system

Including instructions for disassembly and recycling: e.g., clear labels with detailed material information, disassembly instructions, and recycling indications for each material and suggested recycling centres

-

Award-winning materials

The challenge for FROLIC studio’s Award-winning materials project was to embed sustainability within the design of an award while keeping a high-end premium character. Designing for recycling was one of the criteria adopted for the award design. The lamp component is made of which can be recycled into new “multipurpose” glass. Moreover, glass that fails during production can be reused directly in place if clear. Instead, if coloured, it will follow the same route as household waste glass. The base is made of recycled plastic from local waste streams. Text is laser-engraved into the base to avoid environmentally harmful inks and increase the chances for successful material recycling. The packaging, untreated hard cardboard wrapped in kraft paper, can also be recycled.

Design for disassembly

If disassembling a product is challenging, manufacturers or users may feel discouraged from, for instance, repairing, reusing, refurbishing, remanufacturing or recycling it and opt to discard it as waste, ultimately losing the value of its materials.

But materials of products which are easy to repair, refurbish and reconfigure can serve as material “banks” for the same or other products, thus returning to productive use at end-of-life.

That’s why, when designing for disassembly, we must design intentionally for easy material recovery, value retention, and meaningful future use.

-

Examining the design process and supply chain backwards: thinking about how a product gets disassembled might make its assembling easier

Keeping the structure accessible and reversible

Trying not to use glue or other adhesives, if possible: e.g., choosing materials that allow for simple and minimal assembly

Designing for modularity: for facilitating replacing obsolete or damaged parts or adding new features

Designing for repair, refurbishing and upgradability

Providing disassembly instructions

-

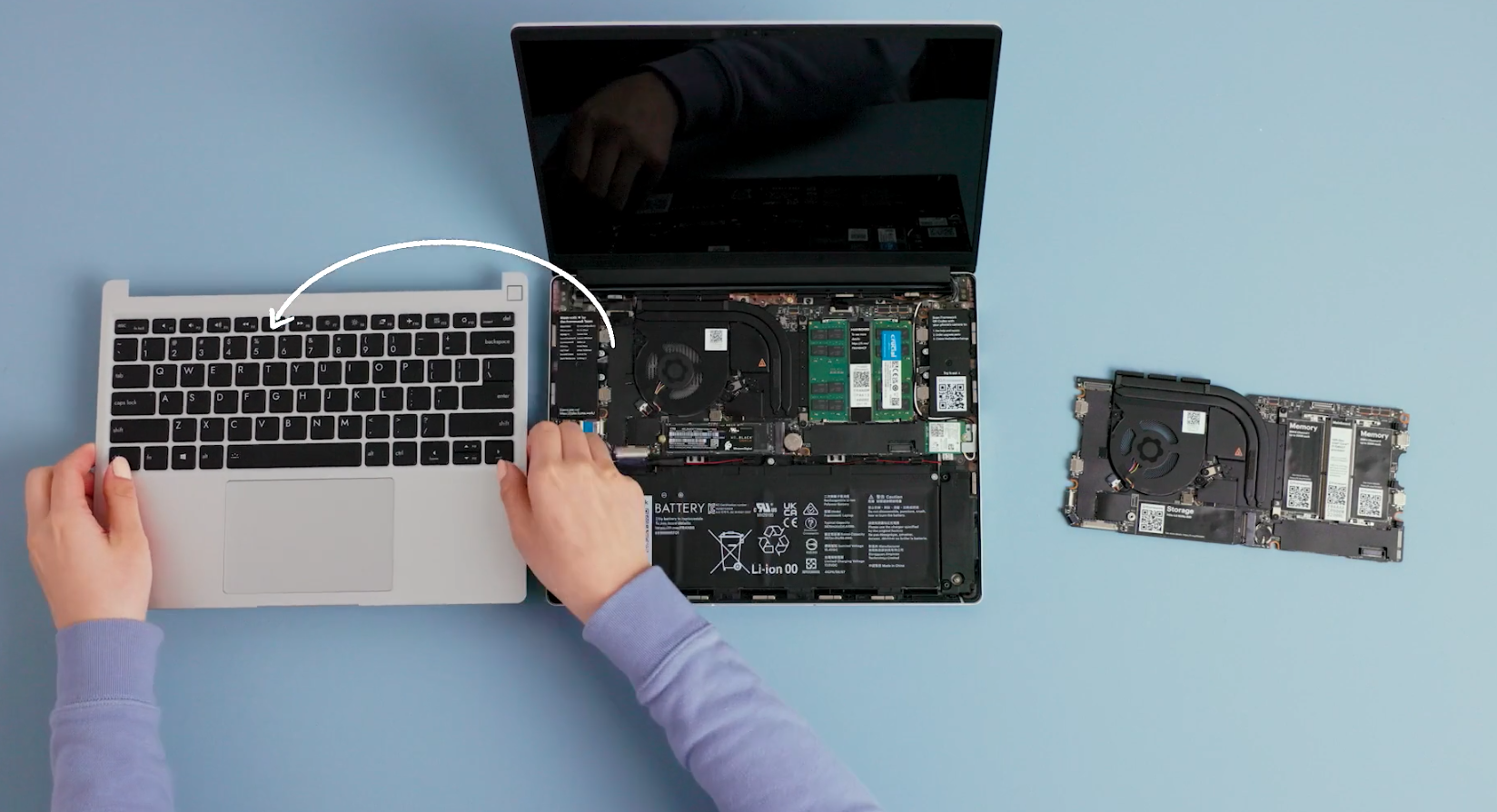

Fairphone

Who does not have at least one “old” phone just sitting around at home, in the back of some drawers, or in our technology boxes? Fairphone reduces e-waste thanks to easy-to-disassemble products. Do you own a Fairphone that could use some help or an upgrade? Do not put it in a drawer, buy a new one and forget about it! Fairphone easy disassembly smartphones allow for easy repair and modular upgrades to make the device’s hardware last as long as possible and provide the support to keep the software up to date. For instance, parts are not glued shut so that the device can also be repaired or updated at home with a standard screwdriver. All modules (e.g., battery, screen or camera) are available in the online shop, and easy-to-follow tutorials are provided. Disassembly enables the devices to be continuously reused, repurposed or recycled. Fairphone also takes phones back. Those that are still usable get their data wholly deleted, components (e.g., the screen or battery) are replaced or fixed if needed and then they are brought back into the market for someone else to enjoy them. When the phones cannot be reused, thanks to easy disassembly, at least their precious materials can be recycled, reused or repurposed.

Design for repair & refurbishing

Why throw away a damaged or worn-out product if it can be efficiently repaired or refurbished? As we said, people opt for convenience, so it all comes down to how easily, quickly, and cheaply the damaged elements can be replaced.

This is ultimately dependent on how we design a product.

Borrowing the words of sociology professor H. Douglas: “Repair is only an extension of making”.

-

Including redundant elements: if one fails, the product still functions

Designing for emotion: people are more likely to want to fix what is valuable to them

Designing for disassembly and modularity: the easier it can come apart, the higher the chances it will get repaired. Ensuring that components can be removed (and replaced) without special tools might help too. Additionally, elements that might quickly fail should be the most accessible to remove. Modules that can get easily disassembled and replaced might encourage users to repair the product themselves or to send the faulty part for repairing

Including a repair and refurbishing guide

Providing a repair and refurbishing service through the product manufacturer

-

Framework

Who has never experienced a problem with a broken electronic device that cannot be fixed, a damaged component that cannot be replaced, or changing needs that the device cannot satisfy anymore? So we spend more money, buy a new one and let someone else deal with it now discarded as waste. Every year, about 7 kg of e-waste is generated per person. Framework intervenes at the root of the problem by making products that last longer to generate less waste. They proved that laptops can still look good, be functional and have a competitive price while being completely repairable. The only tool needed is a screwdriver which is included in the laptop box. Product returns get refurbished and sold at a lower price. Additionally, enabling easy repair has opened up opportunities for laptop upgradeability and customisation. If the users’ needs change, the laptop changes with them. Setup, repair, and upgrade guides and a community support environment are available on the website, together with all replacement parts which can be purchased at need.

Design for reuse & repurpose

Products get thrown away not only when they break: trends, technologies, and social changes might make a product less functional or attractive, or even obsolete.

However, designing reusable and repurposable products expands their lifetimes and saves resources for their disposal, end-of-life processing, and the production of new items.

Note: “Reuse” refers to reusing a discarded product that is still in good condition and fulfils its original function. “Repurpose” refers to using a discarded product, its parts or materials in a new product with a different function.

-

Ensuring the durability and reliability of materials

Designing for disassembly, modularity, repair, refurbishing, and recycling

Increasing loyalty and trust of users to the product

Including a “material passport”: indicating materials, what they are made of and how they can be safely reintegrated for reuse or repurpose

Implementing a free take-back service: offering to take back the product once it has reached its end-of-life to ensure materials make their way back to a supply stream and be either reused or repurposed

Providing products as a service: leasing products instead of selling them to ensure materials make their way back to a supply stream

-

Repeat

Why shouldn't products last a lifetime? Repeat headphones claim to do that. 85% of the devices' components can be reused thanks to their durable, standardised, modular and easy-to-disassemble design. How? Replacement components are available on Repeat's website and sent with a pre-paid return envelope for the damaged part, ensuring the reuse of the pieces in new devices (or, if not possible, recycled). Customers can also return the headphones for an upgrade or complete replacement. Combining all this with a subscription business model, Repeat maximises the use cycles for every pair of headphones. An active monthly membership grants subscribers a free device they can change, repair or return whenever they want. Customers can also purchase the product without a subscription plan and only opt (or not) for an "Unlimited Repairs" per year or forever plan.

Reducing

FROLIC studio. Fossil fuel-free crib (picture by Yvonne Witte).

This principle seems to be quite relevant in the current effort to detach ourselves from our dependence on fossil fuels.

In fact, when we bring "reducing" in the design process, we aim to increase the efficiency of product manufacture and, or use by consuming fewer resources and materials

-

Sticking only to what is necessary: say no to additional materials, features, or even to the product itself, if they do not serve a fundamental purpose

Saying no, if it is likely to produce harm

Reducing or avoiding non-renewable resources or raw materials usage

Sourcing materials and manufacturing products locally

Interrogating the supply chain through the lens of fossil fuel use: examining not just the product's composition but its sourcing, transportation and complete processing

Implementing a take-back service: offering to take back the product once it has reached its end-of-life to ensure materials make their way back to a supply stream so that fewer "new" materials are needed

Providing products as a service: leasing products instead of selling them to keep material and products circulating

-

Fossil fuel-free crib

FROLIC studio's fossil fuel-free crib was built to industry standard without using a single gram of coal, oil or gas at any stage of manufacturing or transportation. This project involved going to great lengths. We located industrial facilities powered by renewable energy and worked with local artisans to apply centuries-old crafting techniques. In addition, we looked for and found leaders in biomaterials as sourcing partners. Finally, we rethought supply chain gaps using electric vehicles. The significant effort required to bring such a design to life highlights our reliance on fossil fuels. Furthermore, it signifies that our planet's future relies on redefining how we manufacture our products.

Refusing & rethinking

FROLIC studio. Smartians.

Steps can and need to be taken to reduce waste and prevent its creation, produce and consume less, and change how we do it.

With “refusing”, we aim to make a product or material redundant by abandoning its function or offering it through a radically different product or material.

With “rethinking”, we aim to extend the use of a product or material by redesigning them in view of circularity (e.g. through sharing products or by putting multi-functional products on the market).

-

Sticking only to what is necessary: say no to additional materials, features, or even to the product itself, if they do not serve a fundamental purpose

Saying no, if it is likely to produce harm

Considering how the consumer will react to the product and its materials: could it be “refused” for a more sustainable choice?

Embedding multi-functionality

Implementing a take-back service: offering to take back the product once it has reached its end-of-life to ensure materials make their way back to a supply stream

Providing products as a service: leasing products instead of selling them to ensure repeated use; the offer for provision, maintenance and disposal of the product becoming a responsibility of the service providers

-

Smartians

At FROLIC studio, we get great satisfaction from searching for meaningful solutions to everyday problems. We wanted to find an innovative and sustainable way to address the issue of people discarding perfectly functional products in favour of new, more innovative versions. Why not encourage consumers to keep their beloved appliances by giving them the freedom to make them smart? And so, we developed Smartians, cloud-connected motors that breathe new life into the things around the home: a product allowing total flexibility to build and rethink the smart home in a fun, efficient, inventive and circular way.

Wrapping it up

As we have introduced in part one of this series, we, designers, are active perpetrators of the linear economy and its detrimental consequences. Luckily, as a radical transformation of how we produce, consume and reuse goods gets increasingly urgent, we can play an integral part in facilitating such systemic change. However, we cannot limit ourselves to only treating symptoms (e.g., material waste). Instead, we need to think about interventions to try and avoid them.

By informing ourselves on sustainable design principles and strategies and implementing them in our design process, we can positively stir the pot to bring about that systemic change needed for a more sustainable world. With this series, we hope to further contribute to the dialogue on sustainable product design.

In the long run, it comes down to us to hold ourselves accountable and start measuring the success of our products not only through the profit they generate but also by their impact on people and the planet.

Did you miss part one? Find it here.